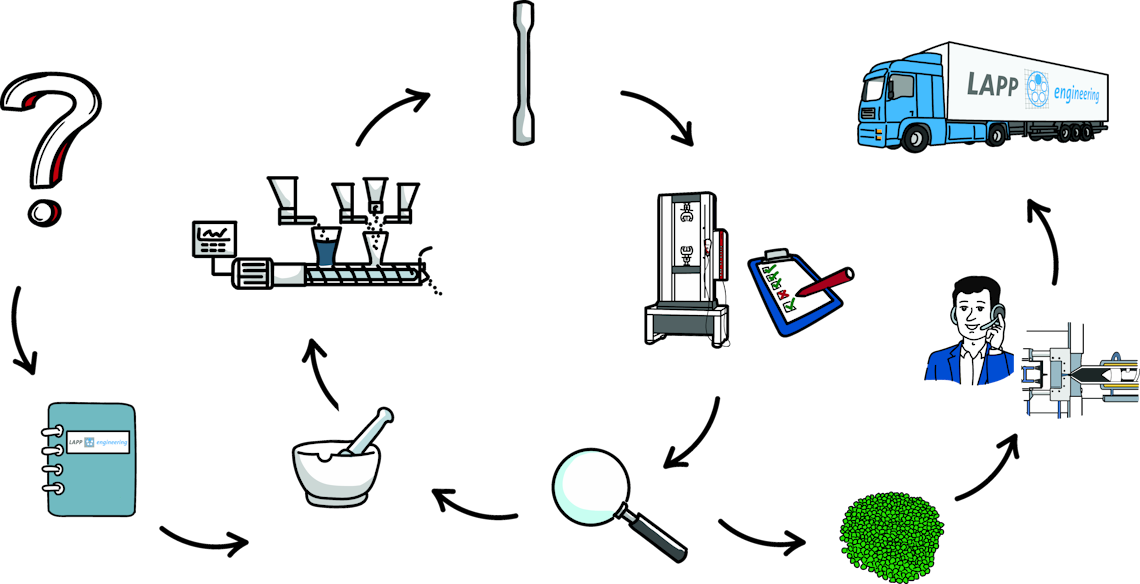

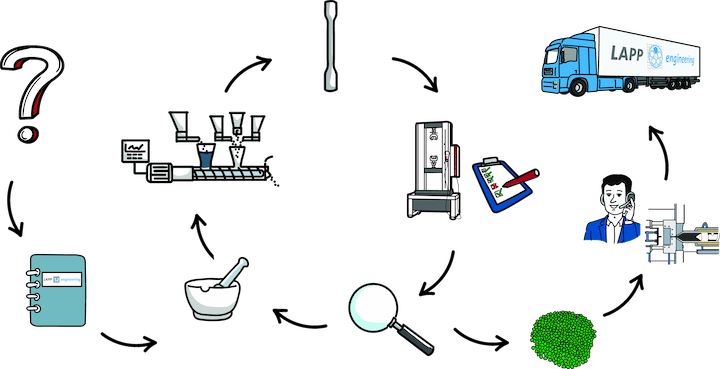

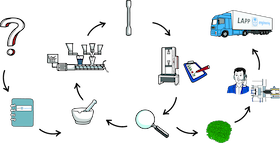

As experts in the area of polymer technology, we accompany our international customers throughout the whole development process. We love and live science und would like to share this passion with you!

From the initial idea through the production of prototypes all the way to batch production of the customized compounds, we offer everything from a single source.

Our Polymer Solutions – Your Customized Compound

In order that your products to stay one step ahead of the competition, we develop your tailor-made polymers– known as compounds. A compound is a very complex product, containing up to 20 single components in form of base polymers, additivies, processing aids, etc. With our experience, our know-how and our equipment, we develop your customized compounds.

An Overview of the Processing Techniques in Polymer Development

Compounding

During compounding different polymers are combined and mixed with selected fillers, additives and processing aids. The resulting compound is made up of at least two, but often up to twenty, different components. Through suitable combinations of materials, synergies are obtained giving the compound optimal properties, which could through one material alone not be attained.

The property profile of a compound can be modified over a broad range. Through the addition of specific additives, the resulting compound can be made more conductive, inexpensive, more flame resistant, crosslinkable, light- and heat resistant, increasingly processable, lubricated, or optically or haptically improved.

To this purpose we develop and optimize formulas for compounds based on specific customer requirements.

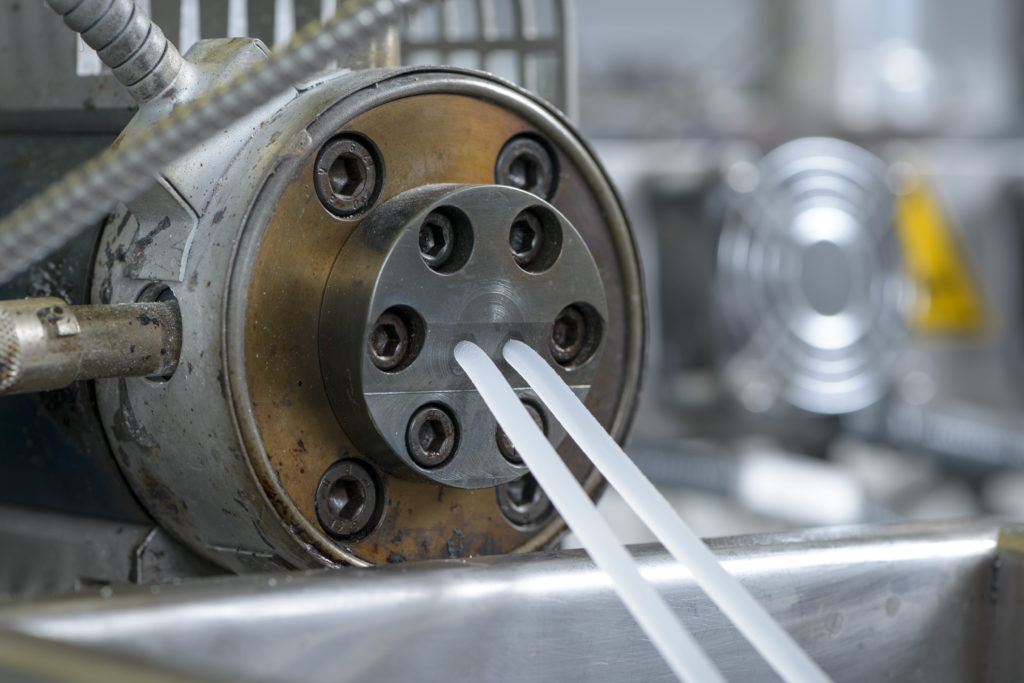

Extrusion

During extrusion the polymer melt is continuously pressed out through a die under high pressure. The resulting profile has the cross section of the nozzle opening and is called extrudate. During the extrusion, the following processes are taking place:

- Feeding of material

- Conveying

- Melting

- Pressure build-up

- Homogenization

Injection Molding

Injection molding is another processing method for plastic materials. During injection molding, the molten polymer gets pressed into a mold (tool) where it cools down to a solid shape. Through opening of the mould, the finished part can be released. Standard materials as well as speciality plastics can be used for injection molding.

Injection molding allows inexpensive and quick production of plastic parts in large quantities. By using particularly enduring molds with high service lives, millions of parts can be produced. Because of its efficiency and flexibility, injection molding is the most widespread production method for the serial production of plastic parts.

Our Technical Centre – Further Equipment

- Laboratory extruder for the production of stripes and simple cable prototypes.

- Injection molding machine for studies of filling ratios and the production of samples (i.e. dog bones) and prototypes.

- Ovens and climatic chamber for aging process.

- Tensile tester equipped with a climate chamber for measurements of the mechanical properties in a temperature range from -80°C to +250°C.

Measurements

We perform hardness measurements, rheological characterization of polymers, tensile- and pressure tests, density measurements and hot-set testing to investigate the level of crosslinking.